Disc spring stacks are widely recognized for their exceptional performance and reliability in demanding applications. These highly engineered components are used across multiple industries, including the subsea sector, where compact, robust, and precise solutions are critical.

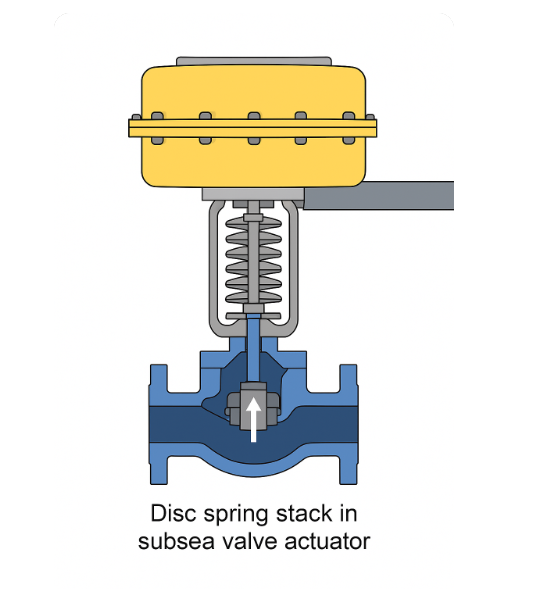

In the energy sector, disc spring stacks are employed in applications ranging from drilling tools to flare stack mechanisms. One of the notable applications is in subsea valve actuators, where they provide reliable force in a compact form factor.

For decades, disc spring stacks have been successfully utilized in the oil industry, and in the early 21st century, the subsea sector began adopting them as well. Compared to traditional coil springs, disc spring stacks offer significant space-saving advantages while delivering the same or greater performance. This makes them ideal for subsea actuator designs, where minimizing size without compromising reliability is essential.

This compact design provides multiple advantages for subsea operators, particularly in reducing weight and minimizing the space required for a complete subsea tree, which may contain up to seven actuators.

The transition from traditional coil springs to disc spring stacks was a gradual engineering process. Teams in the subsea sector spent several years developing large disc spring stacks with an innovative wire-centering method, allowing them to function in the horizontal plane without additional guidance. This design enables actuators to accommodate varying internal diameters while maintaining minimal contact with the springs, optimizing performance and reliability.

The prototype disc springs were tested in purpose-built horizontal fixtures that accurately replicated subsea conditions. “Cans” matching the final actuator design were constructed, and the system was operated using the same control fluid as in field applications. The prototypes not only met but exceeded industry standards for faultless valve operation prior to delivery for customer in-house testing and third-party verification.

In fatigue life testing, several spring stacks were cycled well beyond the required number of repetitions defined by industry standards, yet they continued to perform reliably, demonstrating exceptional durability and long-term operational performance under demanding subsea conditions.

The longevity of these disc spring stacks can be attributed to their robust design and stringent quality management throughout the manufacturing process. From raw material selection to assembly and testing of the complete spring stack, every stage is carefully controlled.

The base material commonly used is chrome vanadium spring steel, a standard in both disc and traditional coil spring production. Advanced manufacturing expertise ensures that physical defects are effectively eliminated, and processes mitigate issues such as hydrogen embrittlement, guaranteeing consistent performance suitable for demanding subsea applications.

HEGONG SPRING ® disc spring stacks are engineered to meet or exceed the most stringent industry standards, including:

ISO 9001: Quality management system

API 6A: Specification for wellhead and christmas tree equipment

DNV/GL & ABS: Certification for subsea and offshore equipment

Compliance with material and performance testing per ASTM standards

These certifications assure customers that the springs are reliable, traceable, and ready for critical subsea operations.

Disc spring stacks are designed to withstand extreme subsea conditions:

High pressure resistance: Suitable for deepwater applications

Corrosion resistance: Advanced coatings and stainless steel options

Temperature range: Operates reliably from -40°C to +150°C

Saltwater endurance: Proven long-term performance in marine environments

HEGONG SPRING ® provides detailed technical data to support engineering decisions:

| Parameter | Typical Range |

|---|---|

| Stack height | 50–500 mm |

| Maximum load | 1–50 kN per stack |

| Travel range | 5–25 mm |

| Spring rate | 10–500 N/mm |

| Operating cycles | ≥1,000,000 without performance degradation |

Custom configurations are available to meet exact force, travel, and size requirements.

Disc spring stacks are engineered for easy integration into subsea actuators:

Horizontal and vertical installation compatible

Minimal guidance required due to wire-centering design

Modular construction enables straightforward replacement of individual springs

Low-maintenance design reduces downtime and operational costs

HEGONG SPRING ® supports both small-quantity and high-volume orders, ensuring reliable supply for critical subsea projects. The disc spring stacks are designed to be compatible with standard subsea actuators and can be custom-engineered for retrofitting or new designs.

Disc spring stacks from HEGONG SPRING ® have been deployed in multiple subsea projects, including deepwater valve actuators and drilling systems. Our products have consistently demonstrated:

Long-term operational reliability

Reduced actuator footprint

Compliance with industry standards

High customer satisfaction and repeat adoption

High-performance disc springs offer several benefits for subsea systems:

Robust and reliable design suitable for demanding environments

Precise control of force and travel to meet exact application requirements

Reduced equipment footprint compared to traditional coil springs

Custom-engineered springs tailored to meet the most stringent operational specifications

Certified and traceable manufacturing for subsea compliance

The use of high-performance disc spring stacks in subsea applications offers key advantages:

Exceptional quality and reliability

Advanced, precise manufacturing processes

Highly engineered design optimized for subsea environments

Proven long-term performance and durability under demanding conditions

Full compliance with subsea industry standards and certifications

When subsea performance cannot be compromised, HEGONG SPRING ® disc spring stacks deliver the reliability, precision, and durability required for the most demanding offshore operations. Choose HEGONG SPRING ® for engineered excellence you can trust.