Disc spring can be used in a single piece, as well in multi pieces with different combinations. It is usual to use disc spring stacks with various combinations to meet your specified applications.

Description

The required various load/deflection characteristics of Belleville disc springs can be obtained from the various stacking combinations. The stack combination methods and load&deflection relation as the table below. Disc spring stacks, also known as Belleville washer stacks, are assemblies created by combining multiple disc springs in parallel, in series, or in a mixed configuration. Stacking disc springs allows engineers to achieve customized load–deflection characteristics that cannot be obtained with a single spring. Whether you require high load capacity, greater deflection, or a balanced performance, disc spring stacks provide an efficient and compact solution.

A disc spring stack is formed by arranging two or more disc springs together. Depending on the stacking arrangement, the overall spring force, deflection, and stiffness of the assembly can be adjusted. This flexibility makes disc spring stacks ideal for demanding applications where precise load management, space optimization, and long service life are critical.

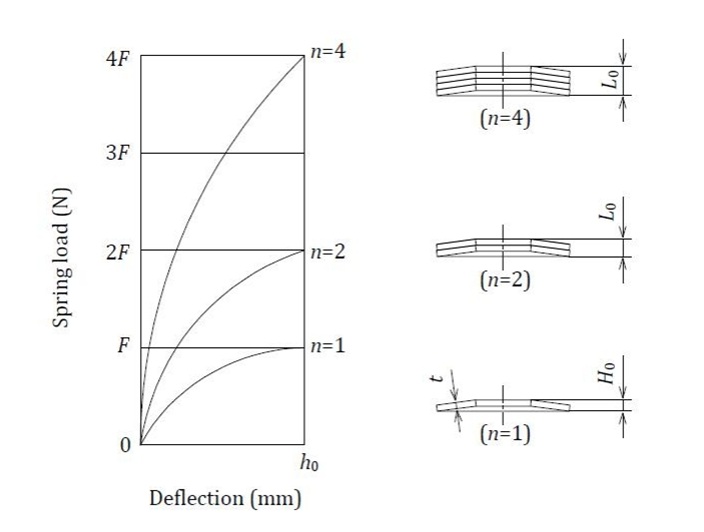

1. Stacking in Parallel |  | The load of the stacking disc springs in parallel will be in direct proportion to the number of single disc springs making up the stack. |

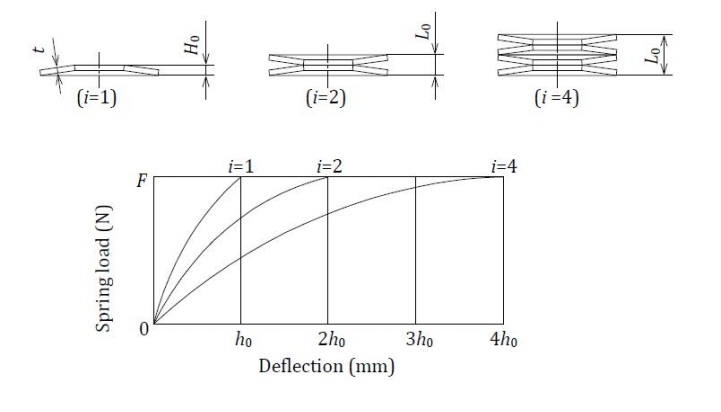

2. Stacking in Series |  | The deflection of stacking disc springs in series will be in direct proportion to the number of single disc springs making up the stack. |

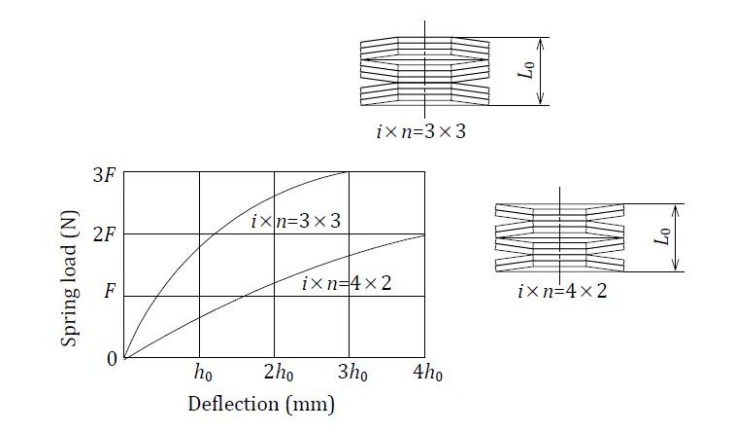

3. Stacking in parallel & series combination |  | Almost any required load/deflection characteristics can be obtained from the different design of stacking combination. |

The designed & expected load/deflection characteristics of disc springs stack just be reached under the correct installation. A guiding element is necessary to keep the disc springs stack in position. This should preferably be a mandrel. HEGONG SPRING® can deliver disc springs stack pre-assembled on a guiding element and highly recommend this way.

1. Provide specific load/deflection data for the whole set of disc springs stack. (HEGONG SPRING®’s load testing machines can measure loads up to 4000KN)

2. Small load tolerance

3. Easier to install

Designing disc spring stacks requires knowledge of load–deflection characteristics and the effects of friction between contacting surfaces.

Parallel Stack Calculation:

Total load = single spring load × number of springs in parallel.

Series Stack Calculation:

Total deflection = single spring deflection × number of springs in series.

Combination Stacks:

Combine both formulas to achieve the desired spring curve.

Additional considerations:

Friction between springs in parallel can reduce overall efficiency.

Lubrication is recommended to reduce wear and improve consistency.

Excessively large stacks may increase assembly complexity and cost.

Dimensions and Designation

Material:

Learn more about MaterialsSurface condition and Corrosion protection:

Learn more details about Corrosion ProtectionTolerance:

Learn more about ToleranceSpecification: