Table of Contents

Introduction

Disc spring stacks offer essential solutions for high-speed packaging machines. They ensure stability, reliability, and efficiency. However, many manufacturers struggle to select the right disc springs. This problem can lead to downtime and increased costs in production. A well-designed spring stack is vital for optimizing performance in packaging systems. Understanding how to effectively implement disc springs can solve these issues.

Summary Answer

Disc spring stack solutions enhance the performance of high-speed packaging machines by providing optimal load support and reducing vibrations. These solutions improve packaging efficiency and minimize wear on machinery.

Subheadings

Overview of Disc Springs

Importance of Stacking Disc Springs

Benefits for High-Speed Packaging Machines

Less vibration, which protects sensitive components

Higher load capacity for heavier packaging materials

Improved cycle times, boosting overall productivity

How to Choose the Right Disc Spring Stack

Load requirements

Operating speeds

Material compatibility

Case Studies: Successful Implementations

What Are Disc Springs?

Disc springs are circular, conical-shaped metal components. They can handle high loads while maintaining flexibility. They are an essential part of many devices in various industries.

Why Stack Springs?

Stacking disc springs increases their load capacity. It allows for better energy absorption. A stack can also offer more flexibility compared to a single spring.

Advantages of Disc Spring Stack Solutions

Using disc spring stacks in packaging machines leads to:

Factors for Selection

When choosing a disc spring stack, consider the following:

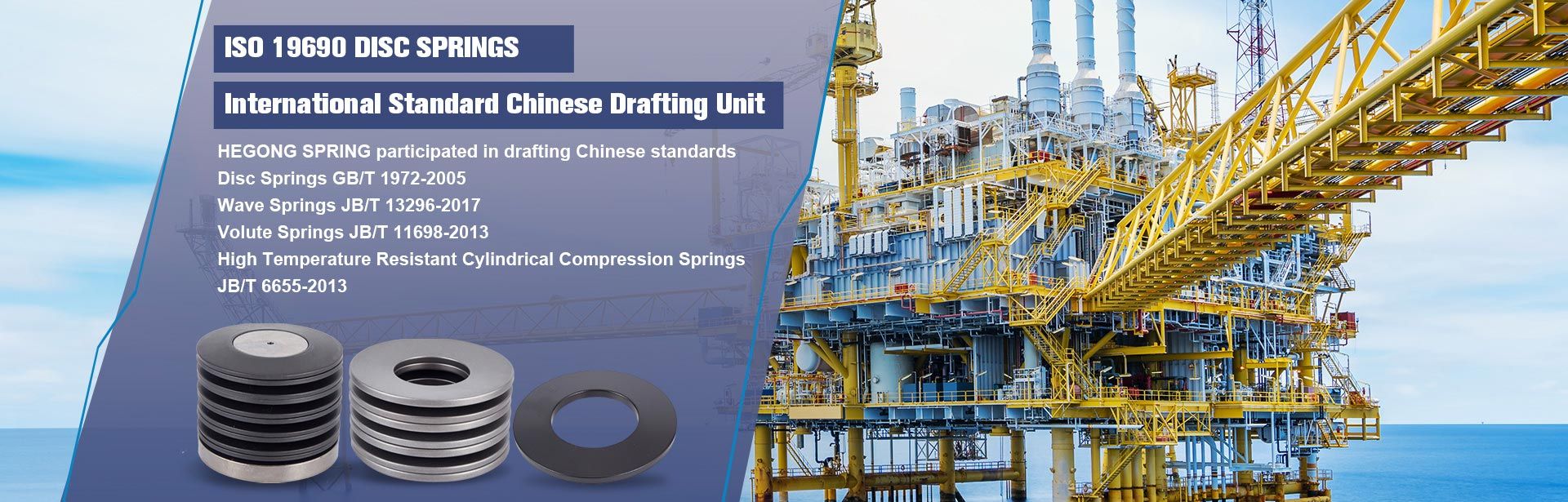

HEGONG SPRING could assist in finding the right configuration for your needs.

Evidence from the Field

Several companies have successfully integrated disc spring stacks into their packaging operations, leading to significant reductions in maintenance costs and downtime.

Conclusion

In summary, disc spring stack solutions for high-speed packaging machines play a crucial role in enhancing operational efficiency. When selected and implemented correctly, these springs can significantly improve performance. Proper understanding of their benefits is essential for achieving success in high-speed packaging applications.

FAQ

What are disc springs used for?

How do I know which disc spring to choose?

Can disc springs reduce machine wear?

What industries use disc springs?

Are stackable disc springs more effective?

How can I contact HEGONG SPRING for assistance?

Disc springs are used to absorb energy, minimize vibrations, and provide support in various machinery, including packaging machines.

Consider factors such as load requirements, speed, and material compatibility to select the right disc spring.

Yes, by minimizing vibrations and distributing loads evenly, disc springs help reduce wear in machines.

Disc springs are used in many industries, including manufacturing, automotive, and food packaging.

Yes, stacking disc springs increases their load capacity and flexibility, making them more effective in high-speed operations.

You can reach out to HEGONG SPRING through their official website or customer service channels for support in choosing the right spring solutions.