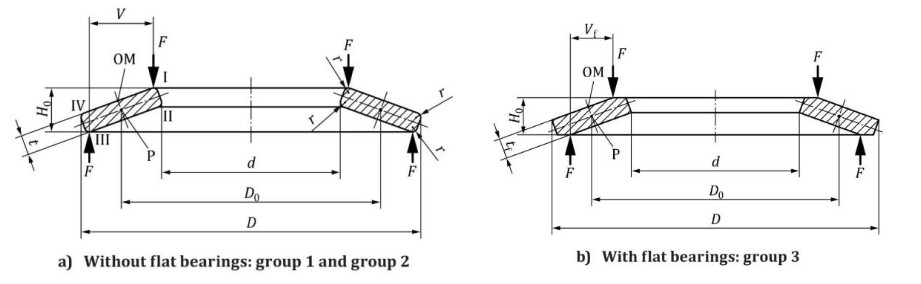

According to the thickness, disc springs are divided into disc springs without flat bearing (group 1,2) and with flat bearing(group 3). As shown in The Figure and Table below.

| Group | tmm | With flat bearing and reduced thickness | Manufacturing process |

| 1 | 0,2 ≤ t < 1,25 | No | Stamping, cold or hot forming, edge rounding |

| 2 | 1,25 ≤ t ≤ 6,0 | Stamping, cold or hot forming, D and d turninga,edge rounding | |

| 3 | 6,0 < t ≤ 14,0 | Yes | Cold or hot forming, turning on all sides, edge rounding or Stampingc, cold or hot forming, D and d turning, edge rounding |

|

a D and d turning are optional. c Stamping without D and d turning is not permitted. |

|||

Dimensional Series based on D/t and h0/t

|

Dimensional series |

ho/t |

tf/t |

D/t |

|

A |

Approx.0,40 |

Approx.0,94 |

Approx.18 |

|

B |

Approx.0,75 |

Approx.0,94 |

Approx.28 |

|

C |

Approx.1,30 |

Approx.0,96 |

Approx.40 |

Comment: The above classification is applicable to the standard parts, non-standard disc springs can be designed and manufactured according to the actual working conditions. Any questions, be free to contact us.