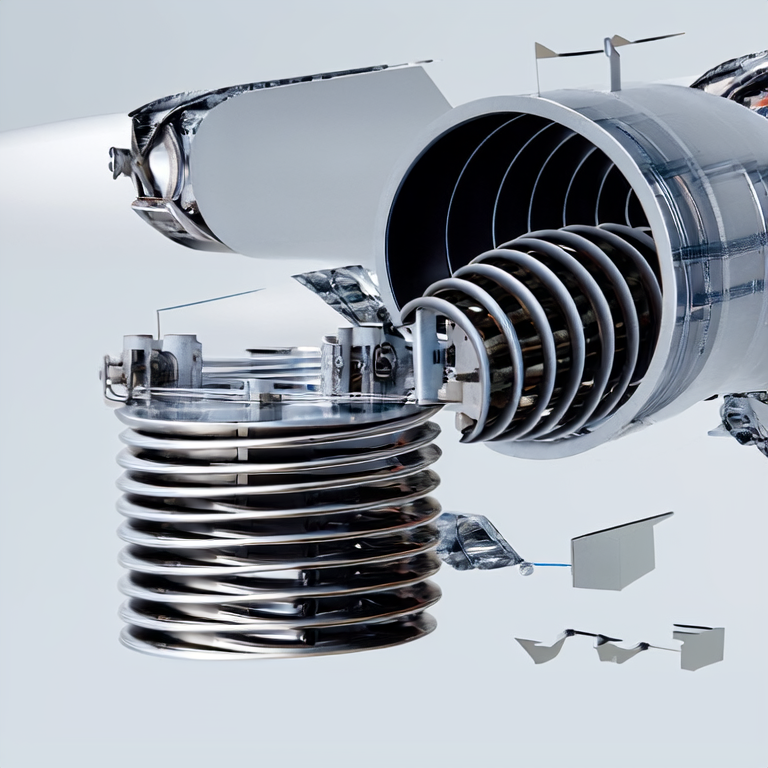

Disc spring stacks provide significant precision in aerospace actuators. Many aerospace applications require components that can withstand high loads while maintaining accuracy. With the increasing need for reliability in aerospace technology, utilizing disc spring stacks has become a popular solution. These springs are designed to be space-efficient and reliable, making them ideal for high-performance environments. By improving force distribution, they help in reducing wear and tear in various systems. This capability makes them essential for aerospace manufacturers focused on performance and safety.

Disc spring stacks enhance precision in aerospace actuators by providing efficient load handling and reducing mechanical stress.

Disc springs can handle higher loads compared to traditional coil springs. This feature allows aerospace actuators to perform reliably in various situations. For instance, they can withstand forces up to 100 tons, making them suitable for heavy-duty applications.

The design of disc spring stacks is very compact. They use minimal space while providing maximum functionality. This compactness is beneficial in crowded aerospace equipment, where space is limited.

Disc springs can endure many cycles of compression and expansion. Their lifespan can reach over a million cycles, making them a cost-effective choice in aerospace engineering. This durability reduces the need for frequent replacements.

Disc spring stacks distribute loads evenly across the components. This uniformity prevents localized stress, leading to longer-lasting equipment.

These springs also serve as efficient energy storage devices. They absorb energy during operation and release it when needed, enhancing actuator performance.

Disc springs are commonly used in landing gear systems. Their ability to absorb shock and distribute weight ensures a smooth landing experience.

In actuator systems, disc spring stacks provide the necessary force for various movements. They are crucial for controlling flaps and other aircraft components.

| Factor | Considerations |

|---|---|

| Load Requirements | Determine maximum and minimum loads the stack will handle. |

| Space Constraints | Ensure the stack fits within the design specifications of the actuator. |

| Fatigue Resistance | Select materials that withstand repeated loads without failure. |

In conclusion, disc spring stacks significantly enhance precision in aerospace actuators. They offer high load capacity, compact design, and exceptional cycle life. Using disc springs ensures reliability and efficiency in demanding aerospace environments, which is crucial for safety and performance. Companies should consider these advantages when selecting components for their designs.

What is a disc spring stack?

A disc spring stack is a type of spring made up of multiple disc-shaped springs stacked together. They are designed to handle high loads and provide reliable performance.

Why are disc springs used in aerospace?

Disc springs are used in aerospace because they are compact, provide high load capacity, and have a long lifespan, making them ideal for critical applications.

How do you choose a disc spring?

To choose a disc spring, consider the load requirements, space constraints, and fatigue resistance according to your application needs.